-

- Synthesis of liquid fuel and value-added chemicals directly from carbon dioxide, the main culprit of greenhouse gas

- Synthesis of liquid fuel and value-added chemicals directly from carbon dioxide, the main culprit of greenhouse gas Professor Jae Hoon Kim's team (Department of Mechanical Engineering) researching the possibility of commercialization through cooperation with domestic oil refiners and contributing to reducing national greenhouse gases in the future. Due to the industrial revolution using coal in the mid-18th century and the discovery of crude oil in the 19th century, humankind has made rapid progress by developing technologies to mass-produce cheap fuels and chemicals. Korea also ranks 5th in the world for its heavy chemical industry development strategy in the 1970s and has the 8th largest oil refining industry in the world.In the 20th century, rapid economic development was achieve globally through the use of fossil fuels such as crude oil and coal, but as a reward, the concentration of CO2 in the atmosphere increased day by day and reached 420 ppm. It has reached a stage that threatens the survival of humankind, such as global warming, ecosystem destruction, sea-level rise and seawater acidification. ProfessorJae-Hoon Kim's research team (Department of Mechanical Engineering) at Sungkyunkwan University has developed a technology that can selectively produce fuels and value-added chemicals by reacting carbon dioxide emitted from industry with renewable hydrogen. The research is expected to contribute to mitigating climate change. The research team developed a technology for synthesizing C5+ long-chain hydrocarbons that can be used as fuel for gasoline and diesel with high selectivity of 77.0% from CO2 using an iron-based catalyst (Na-FeAlOx) with an alumina promoter. The results were published in ACS Catalysis at 2020 [ACS Catalysis, 2020, 10, 10325−10338]. Through this study, the research team identified the principle of the synthesis mechanism of alpha-olefin, a precursor of aromatic compounds, in iron-based catalysts. [Reaction mechanism of CO2 in the Na-FeAlOx catalyst] The research team confirmed that it was possible to produce aromatic compounds from carbon dioxide with a high CO2 conversion rate of 45% and a high aromatic selectivity of 39% by using a composite catalyst combining iron-based catalyst and zeolite. The results were published in Applied Catalysis B:Environmental at 2022 [Applied Catalysis B: Environmental, 2022, 301, 120813]. In particular, the selectivity of BTX among aromatic compounds was high at 59% by controlling the acid site of zeolite. The highly value-added aromatic compound refers to benzene, toluene, xylene, etc. These essential chemical materials rank first in total petro chemical production. [Na-FeAlOx/zeolite Synthesis of aromatic compounds directly from CO2 in complex catalysts] In addition, the research team developed the world's first process that can operate for over 1425 hours with a high yield of about 20% of C5+ long-chain hydrocarbons from CO2 using a cobalt-based catalyst. The results were published in Applied Catalysis B: Environmental at 2022 [AppliedCatalysis B: Environmental, 2022, 305, 121041]. Furthermore, the cobalt-based catalyst newly developed by the research team laid the foundation for the production of promising liquid fuels and lube base oils because the catalysts exhibit high C5+ and C21+ selectivity in the conversion of CO2. In addition, the research team designed a nickel-zinc alloy catalyst capable of synthesizing high value-added chemical materials such as acetic acid and propionic acid by direct hydrogenation of CO2, and published the results in ACS Catalysis at 2021 [ACS Catalysis, 2021, 11,8382–8398]. [Mechanism of direct long-chain hydrocarbon synthesis from CO2 using Na-CoMnOxcatalyst] Currently,Professor Jae-Hoon Kim's research team is researching the possibility ofcommercialization in collaboration with a domestic oil refinery. It intends tocontribute to reducing national greenhouse gases in the future.

-

- 작성일 2022-05-27

- 조회수 5300

-

- BK21FOUR Education Research Group (Department of Chemical Engineering) International Online Workshop

- Department of Chemical Engineering’s BK21FOUR Education Research Group holds Cooperative International Online Workshop with HUST of China SKKU Department of Chemical Engineering Education Research Group (Sustainable Chemical Engineering Global Leader Fostering Education Research Group, Leader Jong Wook, Bae) opened the “7th SKKU-HUST Bilateral Graduate Student Workshop and Annual Academic Conference for Graduate Students” online for two days from April 18th ~ 19th with Huazhong University of Science and Technology(HUST) from Wuhan, China. Since the first Cooperative Academic Conference in November 2015, this 7th international cooperative conference has been held online with about 400 participants, including Dean of Engineering College Nae Eung, LEE, Director of Planning and Coordination Jun Young, Lee, and numerous Chemical Engineering professors. The speakers of this workshop were: Professor Young C. Jang (HUST, Georgia Institute of Technology), Professor Noritatsu Tsubaki (University of Toyama), Professor Michikazu Hara (Tokyo Institute of Technology), Professor Sae Byeok Jo (SKKU), Professor Soo Yeon Cho (SKKU), Professor Joshua Jackman (SKKU), Professor Woo Seok Yang (SKKU). There were also 68 oral presentations of graduate students, deep discussion about the latest research trends and results about bio, energy, the chemical process of information materials, and awards granted to excellent student speakers selected by examination according to each session. There will be 8th workshop at SKKU in 2023, the two schools would be opening the Cooperative International Conference to sustain cooperative research and international communications of graduate students between SKKU and HUST.

-

- 작성일 2022-04-28

- 조회수 5389

-

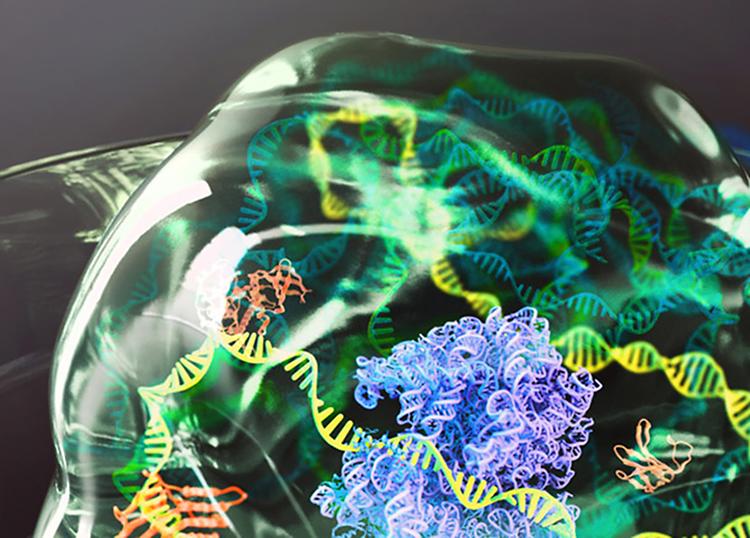

- "In vitro functional protein expression using messenger RNA hydrogel" by Prof. SoongHo Um's team

- Professor Soong Ho Um's research team in the School of Chemical Engineering has published the "In vitro functional protein expression using messenger RNA hydrogel" in collaboration with a nucleic acid nanotechnology company, Progeneer incorporation - It makes RNA itself overcome RNA intrinsic limitations such as precise structure formation and stability - It mass-produces the desired functional proteins at low costs within a short period of time - It is published in the top-classified, world-renowned journal, Advanced Materials (IF = 30.849) On April 5th, a research paper titled “Protein-encoding free-standing RNA hydrogel for sub-compartmentalized translation”, written by Professor Soong Ho Um in the School of Chemical Engineering, was published online in the Advanced Materials (IF =30.849) as a cover paper in recognition of its excellence. The research study was conducted in collaboration with Progeneer Inc., a domestic bio-venture company. And the results are expected to be used in various biopharmaceutical fields such as cytokine for several medical uses and personalized new drugs because of the outstanding advantages of being able to produce large amounts of functional proteins in a short time. The team created a new messenger RNA hydrogel structure with physiological and chemical functions by applying the rolling circle transcription and regularly arranging nucleic acid quadruple helical structures based on nucleic acid nanotechnology. It is well known that RNA plays a very pivotal role in the regulation and expression of biological activity in vivo, but it is unstable and not easy to produce the desired design. In a situation where these serious and essential limitations are pointed out, this study suggests a wise solution. The team’s research has proved that the biological regulator role of natural RNAs such as enzyme catalyst action and protein synthesis is actually possible outside of cells through bio-inspiration. This technology has exactly reproduced the ‘Spatiotemporal RNA-derived RNA phase transformation’ that occurs in the translation process of the central dogma process, the central principle of life, and thus enabled protein mass-production through gel internal compartmentalization. Since the 1950s, by “cell-free protein expression” technology, protein production could be done outside the cell. With the rapid development of the modern biopharmaceutical market, this is receiving global attention. This study has also contributed to significantly maximizing the efficiency, which is a fatal disadvantage of cell-free protein expression technology. Also, the gel form of RNA is made possible for the first time and the RNA having the various functions relatively secures the high mechanical property. This suggests the possibility of developing new materials equipped with genetic information. The research’s universal applicability, which solves the fundamental issue of RNA and contributes to the central principle of life, is expected to create various applied technology to pioneer in a new area of research. [Research Overview] Examples of massproduction of functional proteins using RNA hydrogels technology In present, Progeneer CEOs, Chul Kim and Young Ku Lee are directly applying the technology to its personalized anti-cancer vaccine project (ProV-001) and achieving a functional protein synthesis pipeline. Professor Um sad: "This research is highly appraised as the first for human-being designing and producing an "RNA factory" combined with cell-free protein expression technology, establishing the pinnacle of advanced bio-inspiration technology. Usually, all proteins are produced effectively by relying on natural cells, which take a long time. This process requires an expensive production system, but in this study, we prove to mass-produce desired functional proteins within a short time and at a low cost. Many renowned researchers in this field have recognized this research's innovation and industrial availability.This technology's fast development of antibody treatment will lower the actual clinical entry threshold and contribute significantly to the development of patient-specific care. " The research was pulished on line on world-renowned journal "Advanced Materials"(IF=30.849)as cover page on April 5th ※ Research Article title : Protein-encoding Free-standing RNA Hydrogel for Sub-compartmentalized Translation

-

- 작성일 2022-04-28

- 조회수 5367

-

- Development of High-Performance Piezoelectric Polymer Fiber Material using Atmospheric Moisture by Advanced Materials

- Development of High-Performance Piezoelectric Polymer Fiber Material using Atmospheric Moisture by Advanced Materials Science and Engineering Professor Kim, Miso - Investigation of electric generation that controls piezoelectric Fiber Polymer structure using atmospheric moisture - The suggestion of self-sustaining fiber motion sensor technology SKKU (President Shin, Dongryeol) Advanced Material Science and Engineering Research team of Professor Kim, Miso (first co-author Researcher Kim, Dabin) developed a self-sustainable fiber motion sensor using atmospheric moisture. The piezoelectric polymer fiber material is eco-friendly among Piezoelectric materials that can generate electricity by mechanical transformation. In addition, it does not include lead and has flexible features, showing potential for medical usage or a wearable self-sustaining sensor. However, the limitation was that performances are poor compared to piezoelectric ceramic materials containing lead. Hence, there was research to enhance piezoelectric performance by controlling the chemical properties of a material. Thus, the research team focused on the structural aspect of piezoelectric material to suggest a method in which structure control enhances the self-sustaining piezoelectric fiber sensor element. Structure with a porous surface rendering superior piezoelectric sensor performance even if it is the same piezoelectric fiber material was theoretically confirmed. [연구그림] Schematicdiagram of the process of forming porous surfaces in textile materials The team identified process conditions for experimental verification to induce porous surfaces using atmospheric moisture. Then, it combined it with the electrospinning method, a fiber-producing method using electricity, to produce porous piezoelectric polymer fiber material successfully. By using piezoelectric polymer fiber with a porous surface, the research team could portray a better self-sustaining motion sensor with higher piezoelectric voltage and electricity performance than the existing one. Prof. Kim, Miso added “Porous structure control method using atmospheric moisture not only enhances piezoelectric fiber-based self-sustaining motion sensor’s performance but also signifies securement of piezoelectric material development technology. This research was supported by: the Ministry of Science and ICT, the primary research support project (mid-size study) promoted by the National Research Foundation of Korea, the Future Materials Discovery Project, and the Nanomaterial Technology Development Project. The research was recently published in the international journal ‘Small’ (IF=13.281) online and was selected as the official publication cover. ※Research Title: “Ambient Humidity-Induced Phase Separation for Fiber Morphology Engineering toward Piezoelectric Self-Powered Sensing”,Small, 2022 ※ URL: https://onlinelibrary.wiley.com/doi/full/10.1002/smll.202105811

-

- 작성일 2022-04-28

- 조회수 5235

-

- Development of environmental friendly electrocatalysts for sustainable green hydrogen production

- Development of environmental friendly electrocatalysts for sustainable green hydrogen production The research team developed environmental-friendly electrocatalysts for sustainable green hydrogen production. Prof. Jung Kyu Kim (School of Chemical Engineering, SKKU) reported his collaboration research achievements with Prof. Uk Sim (Department of Materials Science & Engineering, Chonnam National University) and NILL Inc. : development of environmental friendly electrocatalysts for sustainable green hydrogen production. First, bimetallic oxides with spinel structures, M2GeO4 (M = Fe, Co), were synthesized via a facile one-pot hydrothermal method and were used as electrocatalysts for urea-assisted water electrolysis to enhance the efficiency of hydrogen production. In alkaline electrolyte with urea, Fe2GeO4, which was used as the anode in the electrolysis cell, reduced the overall input potential to produce H2. The superior performance of Fe2GeO4 in the urea-added water electrolysis was attributed to the higher oxidation state of its metal cations, larger electrochemical active surface area, and lower charge transfer resistance than those of Co2GeO4. Hence, Fe2GeO4 showed 5.49 times higher H2 peak intensity than Co2GeO4, indicating higher efficiency of H2 production. Second, single-phase metal-rich nickel phosphide (Ni12P5)-incorporated carbon composites were designed for a highly efficient water-splitting system. The distinct Ni12P5 is anchored in nitrogen (N)- and phosphorus (P)-rich carbon matrices (Ni12P5@N,P-C); the creation of the matrices entails a facile hydrothermal-followed pyrolysis treatment to explore their bifunctional activities in the water-splitting system. The Ni12P5@N,P-C composite-based two-electrode water-splitting system shows a low operating potential of 1.57 V at 10 mA cm–2 and achieves the commercially required high current density of 500 mA cm–2 at a stable potential of 2 V. The functionalization of composite electrocatalysts based on strategical engineering and the intrusion of multiple active sites can help develop enhanced electrochemical energy systems. These two research achievements were selected as the front cover art of journals ‘Environmental Science: Nano (DOI: 10.1039/D1EN00529D)’ and ‘ACS Sustainable Chemistry & Engineering (DOI: 10.1021/acssuschemeng.1c06514)’, respectively. *Paper 1 : Boosting eco-friendly hydrogen generation by urea-assisted water electrolysis using M2GeO4 (M = Fe, Co) as an active electrocatalyst (저널: Environmental Science: Nano, DOI: 10.1039/D1EN00529D) *Paper 2 : Anchoring of Ni12P5 Microbricks in Nitrogen- and Phosphorus-Enriched Carbon Frameworks: Engineering Bifunctional Active Sites for Efficient Water-Splitting Systems (저널: ACS Sustainable Chemistry & Engineering, DOI: 10.1021/acssuschemeng.1c06514)

-

- 작성일 2022-03-21

- 조회수 3774

-

- Unveiling the impact of Fe incorporation on intrinsic performance of reconstructed water oxidation electrocatalyst

- Unveiling the impact of Fe incorporation on intrinsic performance of reconstructed water oxidation electrocatalyst Securing the source technology for next generation ultra-high efficiency/stability electrocatalysts Chemical Engineering Professor Pil Jin Yoo’s group (with Drs. Clament Sagaya Selvam and Gwan Hyun Choi) at school of chemical engineering announced that highly efficient and extremely stable oxygen evolution reaction (OER) electrocatalysts have been developed for the next generation water electrolysis technology. With a successful co-working with profs. Won-Sub Yoon (Department of Energy Science) and Won Bo Lee (Seoul National University) groups, in this work, they investigated the fundamental mechanism of dynamic interactions between electrolyte and electrocatalyst surface through experimental and theoretical way. This work was published in ACS Energy Letters (Impact Factor: 23.101) featured as a cover paper. Thanks to its environmental benignity, the water electrolysis technology has received great interest both from academy and industry as a promising solution for producing clean hydrogen energy. During the electrolysis of water into hydrogen and oxygen gases, while the reaction side for the hydrogen evolution reaction proceeds in a relatively smooth and stable way, the concurrently occurring OER reaction generally suffers from high overpotential and degradation of electrocatalysts, hindering the practical and commercial utilization of the water electrolysis to the market. To challenge this issue, the SKKU research team first proposed the nanostructured cobalt-sulfur hybrids (Co9S8) as a basic electro-conductive platform for high performance OER and subsequently electro-deposited a thin layer of nickel oxyhydroxide (NiOOH) over the surface of Co9S8 to simultaneously impart the erosion stability and electrochemical activity. In addition, for the first time, they elucidated that the enhanced electrocatalytic performance was originated from the self-Fe-doping of the catalyst surface as a result of dynamic interactions with the electrolyte. With regard to this technological advance, prof. Yoo commented that “This approach would offer a new design toolkit for high performance OER electrocatalysts and it is greatly anticipated for being extensively utilized for materials in eco-friendly energy technology”. Prof. Yoo group has also reported leading-edge research result on novel electrocatalysts in Energy & Environmental Science (Impact Factor: 38.532) in May. This work was published on December 10th in ACS Energy Letters (Impact Factor: 23.101) as a cover paper with the governmental funding support of NRF 2018M3D1A1058624, 2020R1A2B5B02002483, and 2021R1A4A1024129. ※ Paper 1 : “Unveiling the Impact of Fe Incorporation on Intrinsic Performance of Reconstructed Water Oxidation Electrocatalyst”, ACS Energy Letters, 6, 4345−4354 (2021). * Paper 2 : “Modularly aromatic-knit graphitizable phenolic network as a tailored platform for electrochemical applications”, Energy & Environmental Science, 14, 3203–3215 (2021).

-

- 작성일 2022-03-21

- 조회수 3747

-

- Professor Wonyoung Lee’s group develops the world’s best-performing proton conducting fuel cell

- Professor Wonyoung Lee’s group develops the world’s best-performing proton conducting fuel cell Professor Wonyoung Lee’s research team (First author, Mingi Choi, Post-doctoral researcher) at the Department of Mechanical Engineering of Sungkyunkwan University (President Dong-Ryeol Shin) announced that preservation of intrinsic properties of proton conducting electrolytes enables the fuel cell performance to remarkably be improved, resulting in world’s best-performing proton conducting fuel cell. Proton conducting fuel cell has been considered as next-generation ceramic based fuel cell type based on its high ionic conductivity and low activation energy for ion conduction. Although proton conducting fuel cell has been expected to demonstrate the high efficiency and high performance at the low temperature, difficulties in manufacturing still has remained challenge, hindering its wide-spread uses. The research team systematically discovered the underlying mechanism of low performance of proton conducting fuel cell than predicted, and revealed that the volatilization of components in crystal structure of electrolyte during the manufacturing process significantly affect to the grain growth and low chemical stability. The research team proposed the breakthrough for suppressing the undesired volatilization of components, resulting in about 5-fold larger grain size than the previously reported values with prefect chemical composition inside the electrolyte. Based on this perfectly stoichiometric electrolyte, a proton conducting fuel cell system demonstrates the world’s best performance at an operating temperature range of 500-650 °C, which greatly exceeds previously reported values. Professor Wonyoung Lee said, “We overcame the technical challenge for manufacturing the proton conducting fuel cell. Especially, since it demonstrated the world’s best performance using non-complicated method, we believe that this technology can be readily commercialized and can open the possibilities of wide-spread utilization of fuel cell for hydrogen powered stationary power plant, contributing the renewable energy society.” This research is supported by the mid-level research support project of the National Research Foundation (No. 2019R1A2C4070158) and the Sejong Science Fellowship support project (No. 2021R1C1C2006657). It was published online on October 16th in Energy & Environmental Science (IF: 38.53, JCR<1%), an international academic journal in the field of energy. [Figure 1] Correlation between chemical composition and grain growth and chemical stability of the proton conducting electrolyte manufactured by control of volatilization of composition. [Figure 2] Effects of the chemical potential of Ba on the phase separation, grain growth, and proton conductivity as a function of the sintering temperature.

-

- 작성일 2022-03-21

- 조회수 3813

-

- Dr. Seong-In Hong, Advanced Materials Science and Engineering, appointed as an assistant professor at Gachon University

- Dr. Seong-In Hong, Advanced Materials Science and Engineering, appointed as an assistant professor at Gachon University Dr. Seong-In Hong (Graduate of the combined Master’s & Ph.D. Program), Advanced Materials Science and Engineering and Multi-Functional Nano Bioelectronics Lab, will start his position as an assistant professor of the department of Physics at Gachon University, starting from March 2022. Dr. Hong, achieved his doctoral degree with his dissertation titled, “Thin film field effect phototransistors” (Advisor: Prof. Sun-Kook Kim) in Feb 2020, and took a Ph.D. course at the University of Texas at Austin. After that, he was appointed as an assistant professor of the department of Physics at Gachon University this year. Dr. Hong mainly studied the physical properties and particles of a next-generation semiconductor and its applications under his advisor, Prof. Kim. These studies are posted in 28 SCI journals, including Nature Communications, Advanced Materials, ACS Nano, etc. In addition, he worked as a research director in 3 research projects, [National Research Foundation (NRF)] Korea-Canada Global Research Association (GRA), [NRF] Creativity Challenge Research, and [Advanced Materials BK] Global Ph.D. Fellowship (GPF) during his graduate courses. However, Dr. Hong also experienced hardships. He changed his major from the Department of Electronic Engineering at Kyung Hee University to the Department of Advanced Materials Science and Engineering at Sungkyunkwan University due to the transfer of the lab. Also, due to the COVID-19 pandemic, he could not apply for a foreign Ph.D. course. But, he has turned these challenges into opportunities thanks to the great encouragement and support of his advisor, Prof. Kim. The change of major has become a good base to understand semiconductor research on various views and integrate the knowledge of both majors, which leads to the appointment as an assistant professor of the Department of Physics, Gachon University. Dr. Hong said, “Thanks to the great academic system of the Department of Advanced Materials Science and Engineering of our university, I could improve my research capabilities.” Also, during the lock-down period due to COVID-19, he kept making an excellent contribution to many researches working as a Ph.D. researcher in the lab of his advisor, Sun-Kook Kim, and waited for the overseas post-doc opportunity. Dr. Hong is now operating the Overwhelming Nano Electronics Laboratory in Gachon University and aims to study on electronics with overwhelming performance and functions by growing up next-generation semiconductor materials.

-

- 작성일 2022-02-28

- 조회수 3806

-

- School of Advanced Materials Science and Engineering Student Won the First Prize in ‘Low Quality Audio Data AI Model Alg

- School of Advanced Materials Science and Engineering Student Won the First Prize in‘Low Quality Audio Data AI Model Algorithm Development Ideathon’ Lee Hyeong Wook (a student of School of Advanced Materials Science and Engineering/Culture and Technology) won first prize (reward: KRW 5,000,000) at ‘Low Quality Audio Data AI Model Algorithm Development Ideathon’ held by Ministry of Science and ICT, National Information Society Agency, and Tmax Enterprise, Inc. Lee’s

-

- 작성일 2022-02-28

- 조회수 3742

-

- Mechanical Engineering Professor Younjea Kim Won the AFMC Distinguished Engineer Award

- Mechanical Engineering Professor Younjea Kim Won the AFMC Distinguished Engineer Award Younjea Kim, a professor of mechanical engineering, won the AFMC Distinguished Engineer Award given by the Asian Fluid Machinery Committee (AFMC). The AFMC is the most prestigious award in the field, and Prof. Kim was recognized for his contribution to the development of this field. Prof. Kim is a well-known scholar not only domestically but also internationally in the field of fluid engineering and fluid machinery. Also, he has been a member of the AFMC since 2015 and an editor of the International Journal of Fluid Machinery and Systems. In 2019, he served as a chairman of the organizing committee of the international academic conference in the field of fluid machinery and hosted the 15th AICFM conference in Korea.

-

- 작성일 2021-11-08

- 조회수 3916